The Green Pledge states the intent to minimize carbon emissions in packaging, distribution and transportation. And, to take away all the plastic used in production. They also wanted to introduce a fully automated production line to improve productivity and the physical work environment.

But let’s start from the beginning. Svenska Krämfabriken used to send their products in plastic boxes and the employees did the packing of the products manually. Since the demand for their products is high, packing and raising boxes is a busy job. To make the work environment better and the packing more efficient they set out to introduce an automated packaging line.

Svenska Krämfabriken also wanted to find a low carbon material for the boxes used to send products to retailers. Having the retailers in mind, they wanted the box to be highly practical as well. Since the retailers unpack and repack for their own customers, the boxes need to be easy to work with.

All boxes ticked – one supplier

“This was a perfect project for us. Since we have the material they were looking for, we sell packaging machines and we have the knowledge and resources to develop custom-made packaging”, says Elisabeth Gyllengren, Account Manager Industry at Stora Enso.

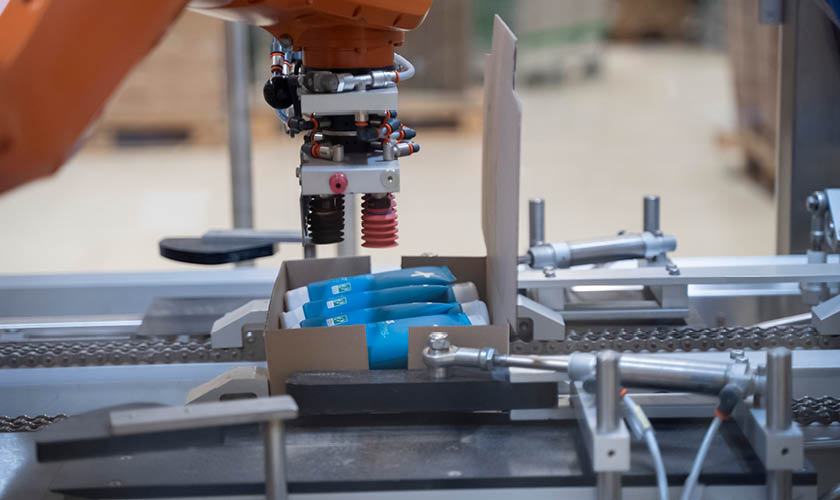

Stora Enso worked together with Svenska Krämfabriken and developed a customized and plastic-free packaging from corrugated board, designed to ship as little air as possible. The packaging generates zero plastic waste and has been produced to be easily opened and recycled which in turn speeds up the logistics for all parties. Stora Enso also delivered and installed a Wrap-Around machine.

“We are super happy with the cooperation, and we ticked all the boxes on our specification for this project. To get the entire solution from one supplier, all the way from box to packaging automation, simplifies a lot”, says Johan Mattsson, CEO & Co-founder.

Results of collaboration:

- A plastic-free, recyclable and renewable box, and a new smart way of packing products in the box to save space

- Reduced use of plastic in wholesale packaging by 15 tonnes per year

- Saving space on pallets by 10-30%, saving 22 truckloads per year

- 10% lower energy use in production per year (equals 150 MWh)

- Improved work environment with a Wrap-Around machine

- Great customer response. The new packaging is easier to work with and it helps Svenska Krämfabriken’s customers within e-commerce in efficiency, warehouse space and recycling

“I’m proud that this new solution is not only good for us and the planet but it also benefits our customers and the whole value chain,” Johan Mattsson ends.