For over-the-counter (OTC) product brand-owners, packaging is critical: high standards for quality and safety mean strict attention to protecting the product inside. On crowded shelves, it’s important to differentiate with packaging that attracts interest, reflects such high standards, and communicates vital information about the product. Furthermore, today’s over-the-counter brands and their retailers seek to improve the sustainability of their packaging and adapt to increasing e-commerce.

How can the physical demands of over-the-counter packaging be achieved sustainably? There are plenty of considerations when evaluating packaging sustainability – and not just limited to the packaging material itself. The true impact of these materials can be studied with verifiable methods like life cycle assessment (LCA). OTC producers and packers need to partner with the right experts who are knowledgeable in the end-use to arrive at packaging solutions that are safe, strong, and sustainable.

Sustainable OTC packaging – what is the way forward?

Packaging begins with choosing the base material. When planning for a new sustainable packaging solution, producers should consider the following regarding the material:

- What base material will be used? Is it renewable, like wood fiber-based material, or is it fossil-based?

- Is the material designed for circularity? Is it recyclable?

- Does the raw material contain recycled content, and can it be traced to its source?

- Does the material meet the end-use demands, e.g., is it strong enough to resist tearing and tolerate humidity?

Choosing renewable materials

Brand-owners have a choice between renewable materials, such as wood fibers, or fossil-based materials. In many examples of OTC packaging, there are multiple materials used including plastic, paperboard, and foil. This is especially the case when primary and secondary packaging are used. Plastic features heavily in the OTC category because of price and performance in product protection. It is possible, however, to significantly reduce plastic and replace it with paperboard – all while achieving the same physical properties. Today’s design possibilities coupled with strong fiber-based material can produce a wide range of attractive, high-performing packaging concepts like paperboard tubes or containers. To learn more about how to choose between fresh or recycled fibers, download white paper here.

Material source and recycled content

Adding recycled content into packaging might seem like a step towards sustainability progress, but it is not a simple “either-or” decision.

Within fiber-based packaging material, OTC producers and packers have a choice between fresh and recycled fiber. Both are recyclable and the fresh fibers’ origin can be traced to sustainably-managed forests. However, the true environmental impact of a package depends on several factors aside from the underlying material. For example, recycling and recycled materials ensure that fibers are used several times and not disposed of after one use, but recycled fiber-based material is often heavier as it requires more fiber to achieve the desired strength for the end-use. This can have an impact on carbon footprint, transport costs, and material usage.

Recycled fibers might also pose a challenge to converting lines and affect runnability, as well as cause dusting during the converting process. Recycled fiber-based material can be used for secondary OTC packaging as it does not come into contact with the product, e.g., when a plastic blister pack is used. It is also a good choice for tertiary packaging in the case of e-commerce.

Factoring in recyclability

It is important to evaluate not only the recyclability of the packaging material itself, but collection rates and infrastructure where the product is marketed and sold. For example, in Europe where recycling infrastructure is excellent, paper and board are recycled at a rate of 83% - a benefit for fiber-based secondary and tertiary packaging. Further, the converting process can also impact recyclability through packaging design, and added laminates, glues, and inks.

All of Stora Enso’s materials are designed and tested for recyclability, therefore helping customers meet their circularity goals and sustainability expectations.

Understanding the climate impact of fresh and recycled fibers with a verified LCA study

The true environmental impact of packaging is due only in part to the raw material used. Other factors over the life cycle, like converting paperboards into packages and transportation, contribute to overall sustainability. Yet by examining specific product examples with the help of LCA, we can quantify the impact and begin to make informed decisions about packaging material sustainability.

For example, a recent third party-verified LCA commissioned by Stora Enso compared the environmental performance of our fresh fiber-based Tambrite™ to average European white-lined chipboard made of partially recycled fibers. The study focused on secondary pharmaceutical packaging as the end-use. The data was collected from converters and the study is based on primary data rather than assumptions on differences.

The results revealed that pharmaceutical packaging made of Tambrite™ yielded better climate performance compared to WLC with an 18% smaller carbon footprint. Recycled fiber-based materials are still beneficial in that they are both renewable and recyclable – an advantage over fossil-based materials. However, white-lined chipboard requires more material to match the stiffness of Tambrite™ and therefore adds more weight to the packaged package – 30% more in the case of this LCA.

Preserving strength and durability

As product protection is the most important feature of OTC packaging, strength and durability cannot be compromised when choosing a packaging material. Neither can be sacrificed when designing packaging with sustainability in mind as these products often require a high degree of protection from light and humidity. Failure to adequately package OTC products results in damage and waste. With expert help, OTC packaging can be optimized to design out unnecessary material while retaining the necessary strength, helping to minimize your packaging’s overall footprint.

Fresh fiber-based Tambrite™ by Stora Enso, for example, is a paperboard material that is high in strength, low in weight, and continuously tested in the pharmaceutical market. When combined with a blister pack, paperboard like Tambrite™ can create the ultimate low-plastic sustainable packaging solution that can support this demanding end-use.

Your brand is unique and so is your solution

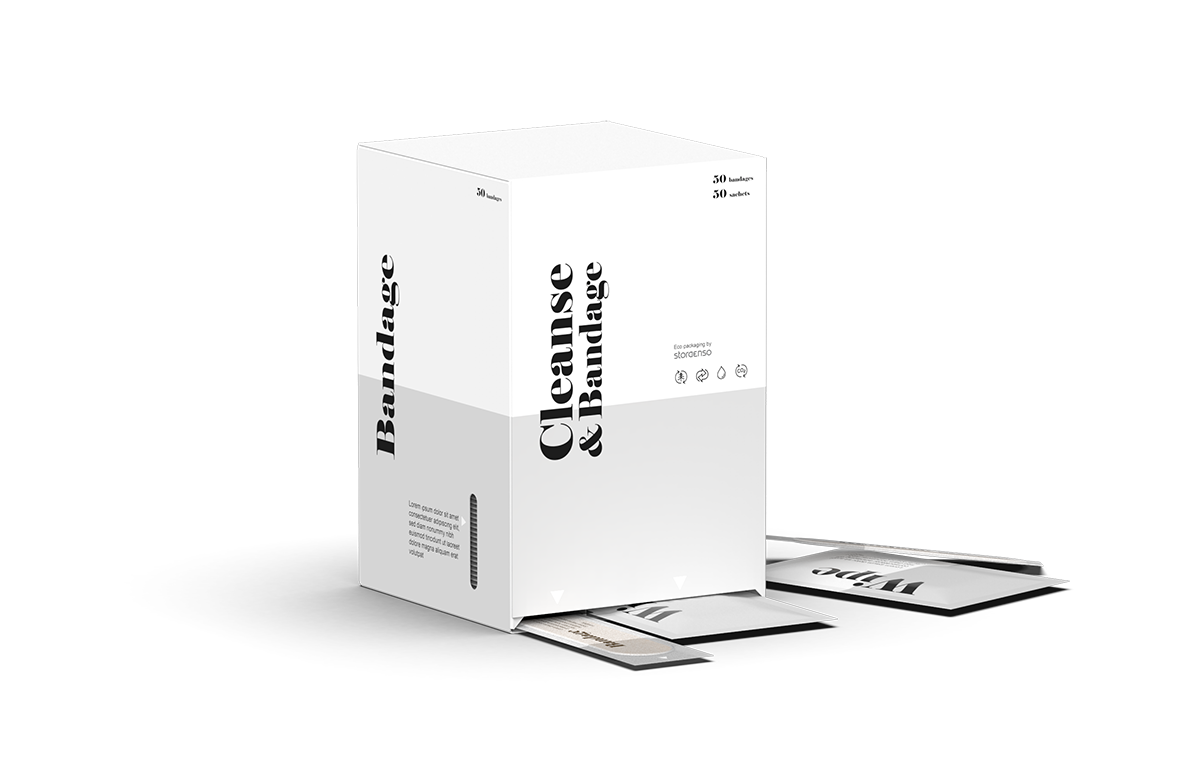

At Stora Enso Packaging Materials, we have been working with producers of OTC pharmaceutical and wellness products for decades, such as outer packages and other cartons in a variety of sizes and shapes. Over the years and together with our customers, we have optimized packaging with features like braille writing, super fast-drying inkjet printing and sheeting, and lightweighting. To ensure our materials meet the strictest quality and performance requirements, we offer ongoing technical customer service and expert design support through Packaging Connects.

If you would like to learn how you can communicate sustainability and differentiate your brand through renewable fiber-based packaging, let’s talk materials and design. Begin by contacting us here.