Glued-laminated timber (GLT/Glulam) is often used in long-span designs, where it can replace steel and concrete in beams, columns, and other load-bearing structures.

Photo: courtesy of Lendlease

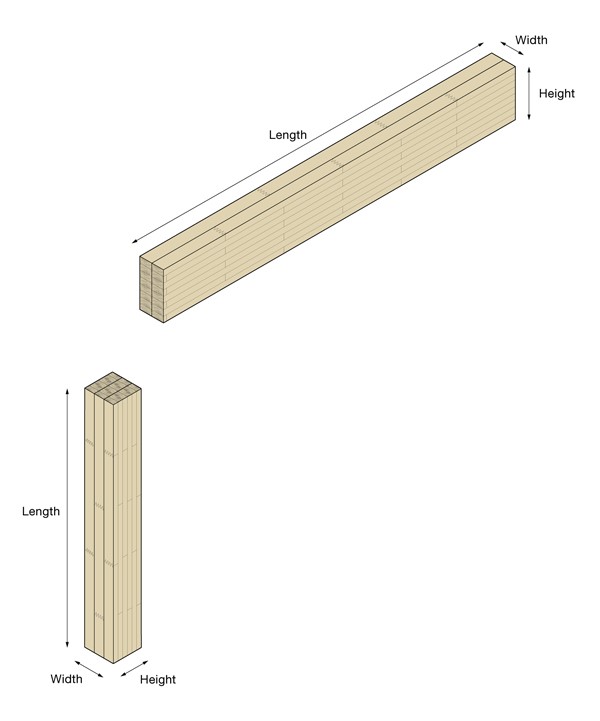

Glued-laminated timber (GLT) or Glulam are different names for the same mass timber product. It can be produced in a wide range of shapes and sizes up to impressive heights and widths.

GLT by Stora Enso is made of strength graded, planed and finger-jointed spruce boards glued together under pressure on their flatwise surface where all boards run parallel to the length to create rectangular cross-sections.

GLT is commonly used in projects where both strength and visual appearance are important. Because of its stability, GLT by Stora Enso does not twist or bend and has highly predictable moisture and fire resistance properties.

GLT by Stora Enso that is customised and delivered just-in-time (JIT) is part of our Sylva™* kit, where it is used in Sylva GLT Beams and Columns.

We work closely with trusted partners to manufacture Sylva™ Beams and Columns from GLT.*Sylva™ by Stora Enso is currently only available in Europe and Australia.

GLT by Stora Enso is made by bonding multiple finger-jointed layers of strength-graded boards together with high-strength adhesive. It can be produced in both standard sizes and custom dimensions to suit long-span designs. To fit the needs of different projects, GLT by Stora Enso is available in visual grade and a more economical industrial grade.

Sylva GLT Beams are made from the strongest parts of the tree, which makes them considerably more sturdy than solid sawn beams of the same size. Depending on budget and requirements, Sylva GLT Beams can be manufactured as homogenous boards (GLh) or combined boards (GLc).

Homogenous boards consist of the same strength of wood throughout, whereas combined boards are manufactured with a mixture of strengths. Higher-strength grade boards are placed in the outer zones and lower-strength grade boards in the inner zone.

All Sylva GLT Beams and Columns are CE-marked and manufactured according to EN 14080 standard.

Block-glued GLT by Stora Enso is a structural member with a solid rectangular cross-section that comprises two or more GLT components bonded together with a structural adhesive.

GLT is a naturally attractive product that strikes an immediate emotional connection and is available in both visual and non-visual grades

Made from solid wood sourced from sustainably managed European forests

Low embodied carbon content compared to steel and concrete

Flexibility—GLT is available in a wide range of widths and heights

Discover the possibilities of mass timber with our 3D tool

| Grade | GL24h, GL28c |

|||||||||||||

| Width, B [mm] | Widths | |||||||||||||

| up to 260 mm in increments of 20 mm | ||||||||||||||

| Height, H up to 1200 mm | 100 | 120 | 140 | - | - | 260 | ||||||||

| 120 |  |

|||||||||||||

| 160 | ||||||||||||||

| 200 | ||||||||||||||

| - | ||||||||||||||

| - | ||||||||||||||

| - | ||||||||||||||

| - | ||||||||||||||

| - | ||||||||||||||

| - | ||||||||||||||

| - | ||||||||||||||

| In increments of 40 mm | - | |||||||||||||

| 1,200 | ||||||||||||||

Lengths up to 18,000 mm |

||||||||||||||

| Grade | GL24h, GL28c |

|||||||||||||

| Width, B [mm] | Block-glued widths | |||||||||||||

| from 280 mm up to 600 mm in increments of 40 mm | ||||||||||||||

| Height, H up to 1200 mm | 280 | 320 | 360 | - | - | 600 | ||||||||

| 280 |  |

|||||||||||||

| 320 | ||||||||||||||

| 360 | ||||||||||||||

| - | ||||||||||||||

| - | ||||||||||||||

| - | ||||||||||||||

| - | ||||||||||||||

| - | ||||||||||||||

| - | ||||||||||||||

| - | ||||||||||||||

| In increments of 40 mm | - | |||||||||||||

| 1,200 | ||||||||||||||

Lengths up to 18,000 mm |

||||||||||||||

Standard variants

Species: Spruce

Strength classes: GL24h, GL28c

Cross-sections: rectangular, linear elements

Surface quality: visual (VI) and industrial quality (IVI)

Standard product range

*80–260 mm in width in increments of 20 mm, block glued from 280 mm up to 600 mm in increments of 40 mm

*up to 1,200 mm in height increments of 40 mm

*18,000 mm in length

* Other dimensions and strength classes can be made available upon request. Please contact your local sales representative for more information.

GLT by Stora Enso is available in two different surface qualities, depending on your requirements.

Learn more about the criteria and how visual and industrial qualities are categorized

Browse over 500 wooden buildings and get inspired

| Service class | Service class 1 and 2 according to EN 1995–1–1 |

| Product certification | CE-marked, manufactured according to EN 14080 |

| Strength class | GL24h, GL28c |

| Moisture content | 12 % ± 2 % (max 15%) |

| Wood species | Spruce |

| Weight/Density | 420kg/m3 (GL24h), 420 kg/m3 (GL28c) |

| Reaction to fire class | Euroclass D–s2, d0 |

| Reaction to fire, charring rate | βn=0.7 mm/min (notional charring according EN 1995–1–2) |

| Thermal conductivity | 0.13 W/(mK) |

| Water vapour transmission resistance | 40 |

GLT by Stora Enso is manufactured in a modern, controlled environment and cut to size with highly accurate CNC processing. Exceptional size accuracy minimises the need for remedial work when the prefabricated elements are delivered on site, which speeds up the building process and reduces construction costs.

| Element length | +/- 2.0 mm |

| Width | +/- 2.0 mm |

| Height | h < 400 mm, -2 mm to + 4 mm h > 400 mm, -0.5 % to 1% |

Wood shrinks or swells as its moisture content changes but in GLT by Stora Enso this is minimal because of the lamination process. Standardized values according to EN 14080 are:

| Direction | % of shrinkage or swelling per % moisture change |

| Grain direction | +/- 0.01 |

| Cross-grain direction | +/- 0.25 |

Calculatis: a state-of-the-art timber design tool