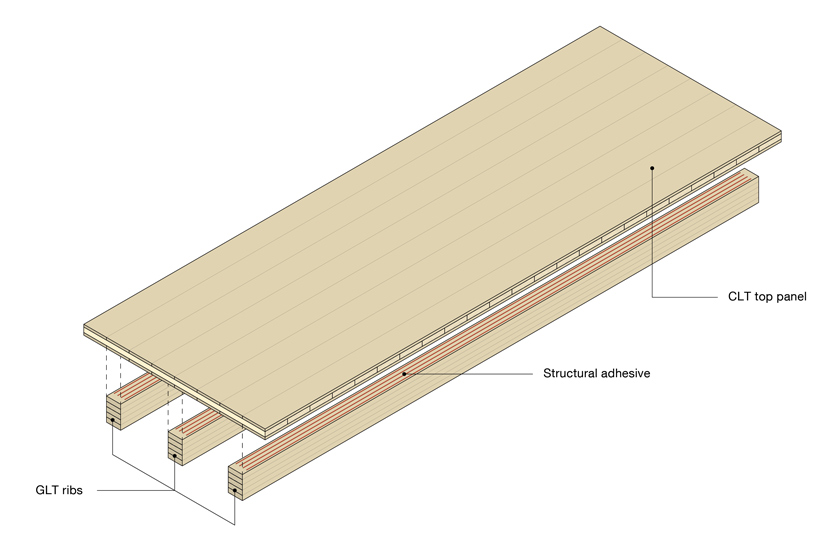

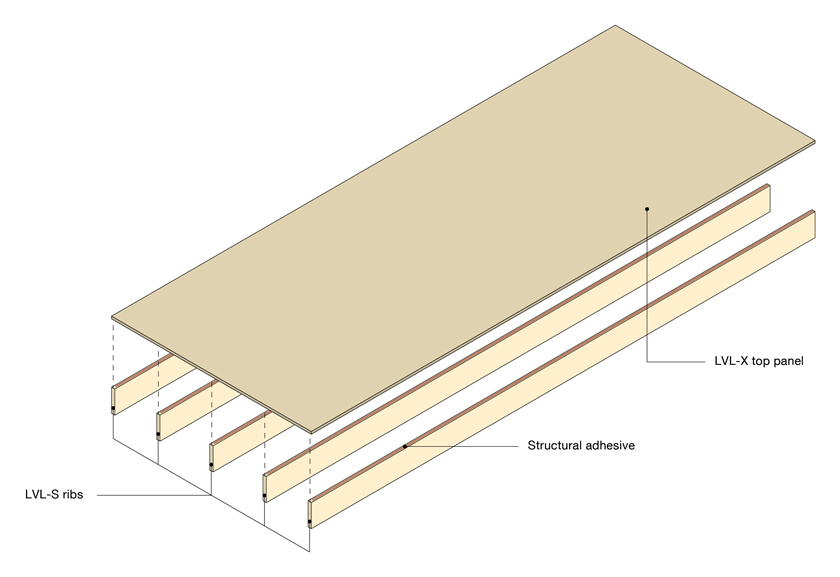

Rib Panels are mass timber products that can be used for long-span floors and roofs where high load-bearing capacity and low self-weight are required. Stora Enso offers two types of Rib Panels: made from CLT combined with GLT (glulam) or from LVL.

Photo: GBL Architectes

Our ready-to-install Rib Panels consist of flat wood panels bonded together with supporting ribs, using structural adhesives that deliver outstanding strength and performance.

Open and flexible floor plans require long-span components to reduce the amount of load-bearing walls and columns. Rib Panels are ideal for spans over 6m, with impressive strength and structural performance.

All Rib Panels by Stora Enso are CE-marked, meaning they meet the European Economic Area's high safety, health, and environmental protection requirements. Precision cut Rib Panels minimise the need for remedial work for the elements to fit in place, speeding up the building process.

Rib Panels that are customised and delivered just-in-time (JIT) are part of our Sylva™* kit, where they can be used in Sylva Floors and Roofs.

*Sylva™ by Stora Enso is currently only available in Europe and Australia.

CLT Rib Panels by Stora Enso are made by bonding a CLT panel and GLT (glulam) ribs with a high-strength adhesive. For outstanding performance, our CLT Rib Panels are made from strength-graded boards. This means we have pre-sorted the wood based on its strength, stiffness, density, and appearance for optimal use.

Our LVL Rib Panels are made from LVL, combining LVL S, where all the veneers run in the same direction, and LVL X, where veneers are regularly spaced at right angles.

The structural bond between the components in Rib Panels by Stora Enso reduces the supporting structure’s depth and optimises the volume of timber material. This gives Rib Panels an advantage over traditional mechanically fastened Rib Panels where the components are simply screwed together. This makes it possible to:

As the only manufacturer with both CE-marked CLT- and LVL Rib Panels, Stora Enso holds European Technical Approvals (ETA) confirming that all Rib Panels by Stora Enso meet the required European health, safety, and environmental protection standards.

Prefabricated and lightweight panels allow for rapid workflow from delivery to assembly

Rib Panels by Stora Enso use wood in the most efficient way possible—yield more m² with less raw material

Floors and roofs made from Rib Panels allow for flexible floor plans that can be easily repurposed for changing needs

Less need for beams and load-bearing walls gives more architectural freedom

Insulation can be integrated into the structural layer of an LVL Rib Panel

The space between the ribs of CLT Rib Panels can be used to route services or other installations

CLT Rib Panels have natural fire-resistant properties and even the structural elements can be left exposed for a beautiful visual surface

Sylva CLT Rib Floors and Roofs are a great fit when the building project requires:

*Sylva™ by Stora Enso is currently only available in Europe and Australia.

Sylva CLT Rib Floors and Roofs are an effective and economical solution for long spans due to their excellent material efficiency. They are available in visual quality, which means it is possible to leave ceilings and soffits exposed. With Sylva CLT Rib Floors and Roofs, it is not necessary to clad the ribs with e.g. gypsum board to meet national fire regulations as the timber structure can remain stable for up to two hours when exposed to a fully developed fire.

Building types

Suitable for residential, office and school buildings with medium to long spans of 6–13m. If longer spans are required, Sylva LVL Rib Floors and Roofs are recommended.

Sylva LVL Rib Floors and Roofs are the ideal choice when the building project requires:

LVL Rib Floors and Roofs are even more material-efficient than CLT Rib Floors and Roofs because they have the lowest weight yet the highest stiffness, load-bearing capacity, and dimensional stability. Due to their high material efficiency and lightweight nature, LVL Rib Floors and Roofs can also be more economical than CLT Rib Floors and Roofs. They can reach longer spans and are well-suited for roof applications with spans between 6–20 m.

Building types

Optimal for residential, school buildings and industrial buildings. LVL Rib Floors and roofs are recommended for spans of 6–20 m.

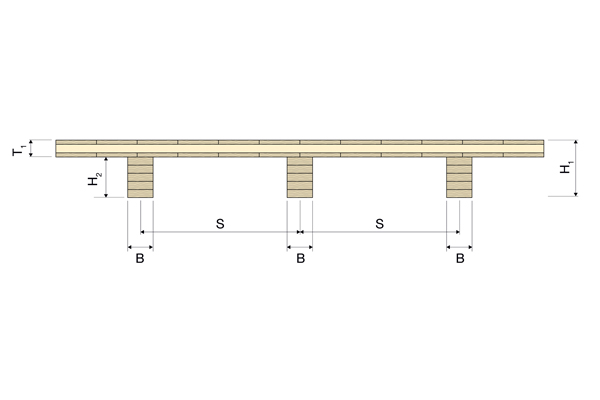

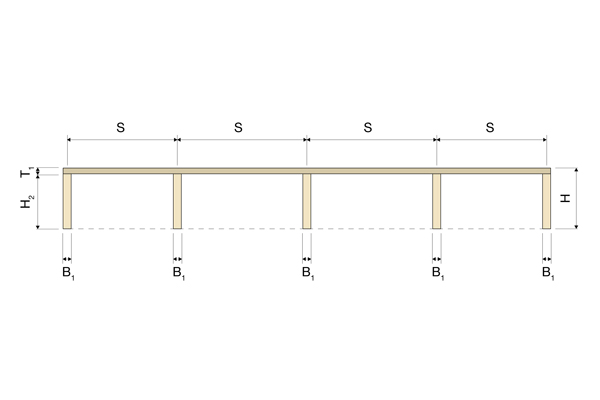

| Sylva CLT Rib Floors | ||||||||||||||

T1 [mm] |

B [mm] |

H2 [mm] |

S | |||||||||||

160 |

200 |

240 | 280 | 320 | 360 | 400 | 440 | 480 | 520 | 560 | ||||

| R30 | 80L3s | 160 |

H280-80L3s | H320-80L3s | H360-80L3s | H400-80L3s | H440-80L3s | H480-80L3s | H520-80L3s | H560-80L3s | H600-80L3s | H640-80L3s | ~800 mm | |

| R60 | 100L3s | 160 |

H260-100L3s | H300-100L3s | H340-100L3s | H380-100L3s | H420-100L3s | H460-100L3s | H500-100L3s | H540-100L3s | H580-100L3s | H620-100L3s | ||

| R90 | 120L3s | 200 |

H400-120L3s | H440-120L3s | H480-120L3s | H520-120L3s | H560-120L3s | |||||||

Standard variants

Length: 5.5 – 20 m

Height: 224 – 636 mm

Width: 2.40 m

| Sylva LVL Rib Roofs | |||||||||||

T1 [mm] |

B1 [mm] |

H2 [mm] |

S |

||||||||

| LVL Grade | X | S | 200 | 240 | 300 | 360 | 400 | 450 | 500 | 600 | |

| R0 | 24 | 51 | H224-X24 | H264-X24 | H324-X24 | H384-X24 | H424-X24 | H474-X24 | H524-X24 | H624-X24 | 600 mm |

| >R0 | Handle with gypsum boards (see ETA) | ||||||||||

| Note - T1 thickness is after calibration sanding which removes 3mm of material. | |||||||||||

| Sylva LVL Rib Floors | |||||||||||

T1 [mm] |

B1 [mm] |

H2 [mm] |

S |

||||||||

| LVL Grade | X | S | 200 | 240 | 300 | 360 | 400 | 450 | 500 | 600 | |

| R0 | 36 | 51 | H236-X36 | H276-X36 | H336-X36 | H396-X36 | H436-X36 | H486-X36 | H536-X36 | H636-X36 | 600 mm |

| >R0 | Handle with gypsum boards (see ETA) | ||||||||||

| Note - T1 thickness is after calibration sanding which removes 3mm of material. | |||||||||||

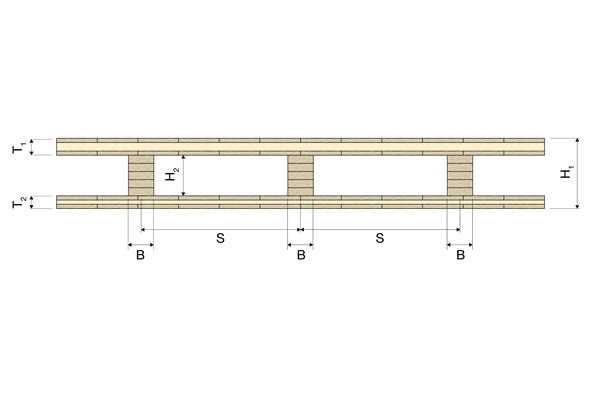

| Sylva LVL Rib Roofs | |||||||||||||

T1 [mm] |

B1 [mm] |

B2 [mm] |

T2 [mm] |

H2 [mm] |

S |

||||||||

| LVL Grade | X | S | S |

200 | 240 | 300 | 360 | 400 | 450 | 500 | 600 | ||

| R0 | 24 | 51 | 300 | 48 | H272-X24-S48F | H312-X24-S48F | H372-X24-S48F | H432-X24-S48F | H472-X24-S48F | H522-X24-S48F | H572-X24-S48F | H672-X24-S48F | 600 |

| >R0 | Handle with gypsum boards (see ETA) | ||||||||||||

| Note - T1 and T2 thickness is after calibration sanding which removes 3mm of material. | |||||||||||||

| Sylva LVL Rib Floors | |||||||||||||

| T1 [mm] | B1 [mm] | B2 [mm] | T2 [mm] | H2 [mm] |

S |

||||||||

| LVL Grade | X | S | S |

200 | 240 | 300 | 360 | 400 | 450 | 500 | |||

| R0 | 36 | 51 | 300 | 48 | H284-X36-S48F | H324-X36-XS48F | H384-X36-S48F | H444-X36-S48F | H484-X36-S48F | H534-X36-S48F | H584-X36-S48F | 600 | |

| >R0 | Handle with gypsum boards (see ETA) | ||||||||||||

| Note - T1 and T2 thickness is after calibration sanding which removes 3mm of material. | |||||||||||||

LVL Rib comprising of a top and bottom panel made from LVL X with LVL S ribs structurally bonded in between.

The additional lower LVL X panel further increases the product's fire and structural performance. It also maximizes the possible span and the potential to decrease the structural depth.

Standard variants

Length: 5.5 – 20 m

Height: 272 – 672 mm

Width: 2.40 m

* Please contact your local sales representative if a non-standard variant is needed.

* Structural depth means the total height required to achieve a certain structural performance or how thick the load-bearing part of the floor needs to be.

| Sylva LVL Rib Roofs | |||||||||||||

T1 [mm] |

B1 [mm] |

T2 [mm] |

H2 [mm] |

S |

|||||||||

| LVL Grade | X | S | X | 200 | 240 | 300 | 360 | 400 | 450 | 500 | 600 | ||

| R0 | 24 | 51 | 48 | H272-X24-X48 | H312-X24-X48 | H372-X24-X48 | H432-X24-X48 | H472-X24-X48 | H522-X24-X48 | H572-X24-X48 | H672-X24-X48 | 600 | |

| >R0 | Handle with gypsum boards (see ETA) | ||||||||||||

| Note - T1 and T2 thickness is after calibration sanding which removes 3mm of material. | |||||||||||||

| Sylva LVL Rib Floors | |||||||||||||

T1 [mm] |

B1 [mm] |

T2 [mm] |

H2 [mm] |

S |

|||||||||

| LVL Grade | X | S | X |

200 | 240 | 300 | 360 | 400 | 450 | ||||

| R0 | 36 | 51 | 48 | H284-X36-X48 | H324-X36-X48 | H384-X36-X48 | H444-X36-X48 | H484-X36-X48 | H534-X36-X48 | 600 | |||

| >R0 | Handle with gypsum boards (see ETA) | ||||||||||||

| Note - T1 and T2 thickness is after calibration sanding which removes 3mm of material. | |||||||||||||

Browse over 500 wooden buildings and get inspired

CLT Rib Panels |

|

| Service class | Service class 1 and 2 to according to EN 1995–1–1 |

| Product certification | CE marked with ETA-20/0893 |

| Strength class | According to ETA-20/0893: CLT panel according to ETA: C24 GLT ribs: GL 20h – GL 32h and GL 20c – GL 32c |

| Moisture content | 11 % ± 3 % |

| Wood species | Spruce (pine or fir also possible) |

| Typical density | ~490 kg/m³. Please note a different density may be declared depending on the need (structural design, transportation, erection etc.) |

| Reaction to fire class | Euroclass D–s2, d0 |

| Resistance to fire, charring rate | According to ETA–20/0893 Annex 4, Fire performance classified according to EN 13501–2 1. Open CLT rib, REI 90 2. Open CLT rib with gypsum board ceiling structure, REI 90 3. Closed CLT rib, REI 90 4. Closed CLT rib with gypsum board ceiling structure, REI 120 |

| Airtightness | CLT is airtight according to EN 12 114 |

| Thermal conductivity of CLT panel | 0.12 W/(mK) according to ETA–20/0893 |

| Water vapour resistance | 50 (dry) to 20 (wet) according to EN ISO 10456 |

LVL Rib Panels |

|

| Service class | Service class 1 and 2 to according to EN 1995–1–1 |

| Product certification | CE marked with ETA 18/1132 |

| Moisture content | 10% +/- 2% when leaving mill |

| Wood species | Spruce |

| Mean density | 510 kg/m³ (LVL S and X) |

| Reaction to fire class | Euroclass D–s1, d0 |

| Resistance to fire, charring rate | According to ETA 18/1132– Annex 2, Fire performance is classified according to EN 13501–2 1. Open LVL rib single fire board ceiling structure, up to REI 30 |

| Airtightness | LVL has adequate airtightness according to ETA 18/1132 |

| Thermal conductivity | 0.13W(mK) according to ETA 18/1132 |

| Water vapour resistance | Wet cup 70 μ Dry cup 200 μ |

Closed LVL Rib Panels can possess inherent fire resistance using the lower LVL X panel as a protective, non-load bearing layer for the remaining LVL Rib Panel. For more information on inherent fire resistance see section above on CLT rib fire performance.

| Depth |

Rib height ≤ 400 mm | -2 / +4 mm |

| Rib height > 400 mm | -0.5% x [height] / +1% x [height] | |

| Width | +/- 2.0 mm | |

| Length | +/- 5.0 mm | |

| Depth | Rib height ≤ 300 mm | ± 2 mm |

| Rib height > 300mm, ≤ 600 mm | ± 3 mm | |

| Rib height > 600 mm | -0.5 %x[height] / +1 %x[height] | |

| Width | ± 2 mm or ± 0.5 % | |

| Height | ± 5 mm | |

| Direction/Component | % of shrinkage or swelling per % moisture change | |

| In plane direction / CLT Panel | +/- 0.02-0.04 | |

| In thickness direction / CLT Panel-GLT ribs | +/- 0.24 | |

Changes are not anticipated in normal conditions for LVL Rib Panels. When necessary, the dimensional change of the product due to the change of moisture content can be calculated as follows:

| Direction | Direction % of shrinkage or swelling per % moisture change | |

| LVL-S | LVL-X | |

| In plane direction | +/- 0.30 | +/- 0.44 |

| In thickness direction | +/- 0.31 | +/- 0.33 |

Calculatis: a state-of-the-art timber design tool

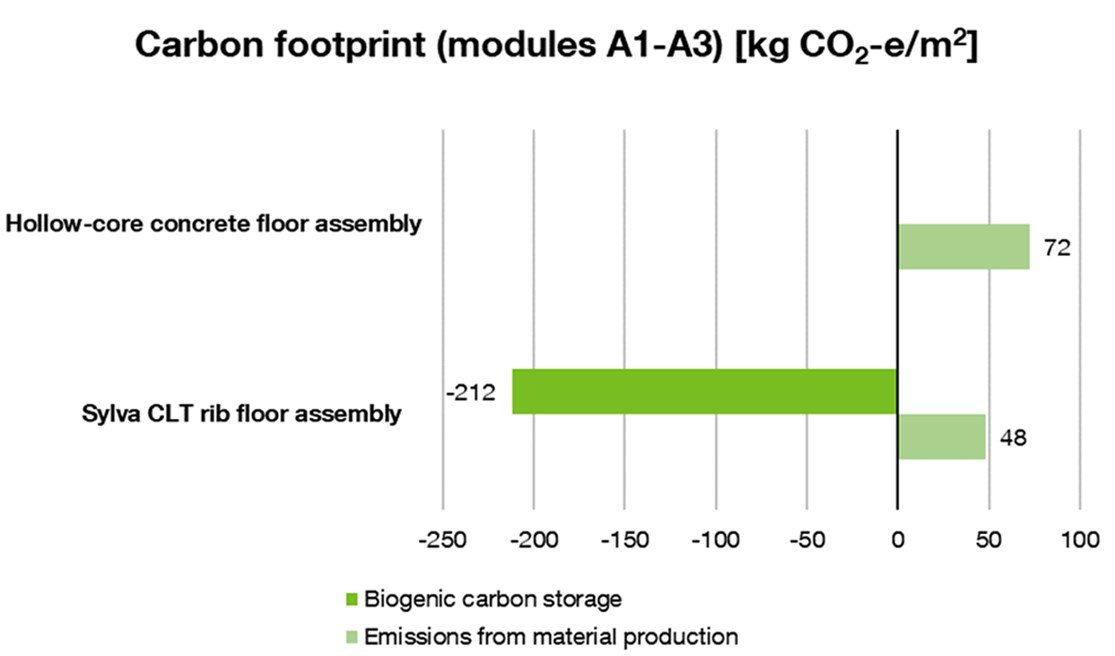

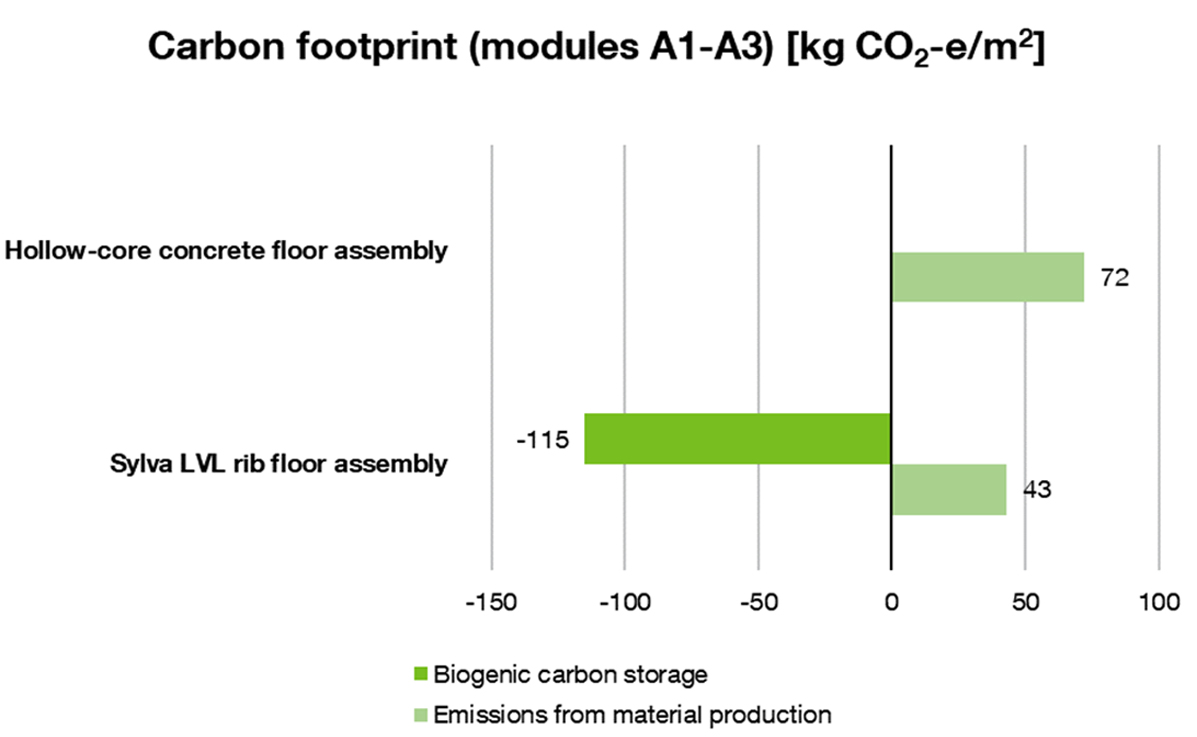

Emission comparison between a Sylva Rib Floor and Concrete

Compared to manufacturing a concrete floor, a Sylva Rib Floor has a significantly smaller carbon footprint CO2 equivalent (eq.). * In addition, the rib floor acts as carbon storage. While the floor locks in the CO2 eq., new CO2 is absorbed by replanted trees.

The compared wall structures are as follows:

Hollow-core concrete floor

-Screed 20 mm

-Glass wool insulation 25 mm

-Concrete 50 mm

-Reinforced steel

-Hollow core concrete slab 265 mm

Sylva Rib Floor (CLT /LVL)

-Screed 50 mm

-Rock wool insulation 50 mm

- CLT/LVL rib panel 360 mm

-Gypsum 12.5 mm

Assumed building:

- European office/residential building, 10,000 m²

The dataset used for this comparison:

- Build-ups - typical European, equivalent build-ups from One Click LCA®—automated life cycle assessment software.

- Sylva CLT rib panel - Stora Enso data from the international EPD® system.

- Sylva LVL rib panel - Stora Enso data from the international EPD® system.

- Other materials—generic data from One Click LCA.

____________________

* Product stage CO2 eq. emissions per m²—the greenhouse gas emissions associated with materials and construction processes up to practical completion modules A1-A3. Excludes the CO2 sequestered in the installed products at practical completion.

An efficient way to use wood for floors and roofs

The amount of wood used per m² can be reduced by up to 40% by using a CLT rib floor and up to 70% by using an LVL rib floor instead of a massive CLT floor.

The example below shows a massive CLT floor and an equivalent Sylva CLT rib floor spanning 8 m in a residential building.

Massive CLT panel

0.26 m³ of wood per m² floor

Sylva CLT Rib Floor

0.16 m³ of wood per m² floor

Sylva LVL Rib Floor

0.07 m³ of wood per m² floor

Building for a sustainable future