Photo: Aalto-yliopisto & Stora Enso / Vesa Loikas

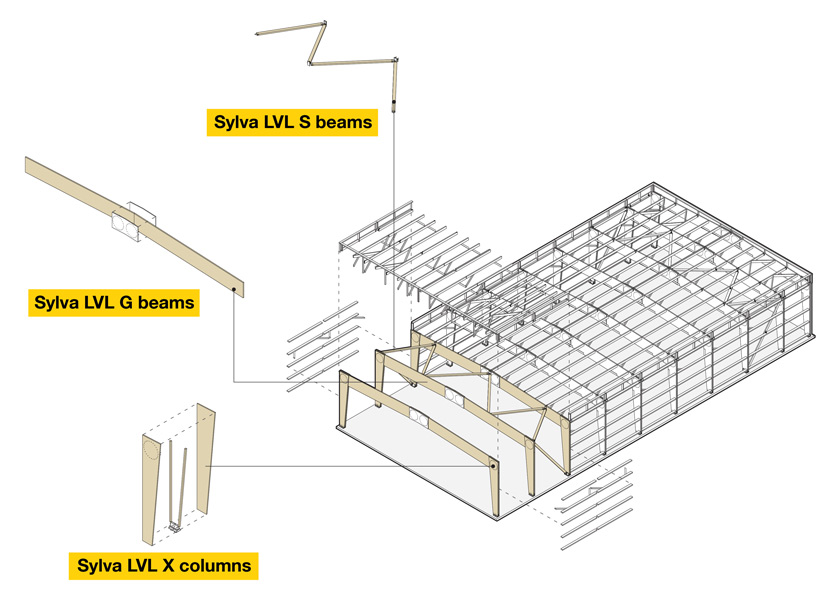

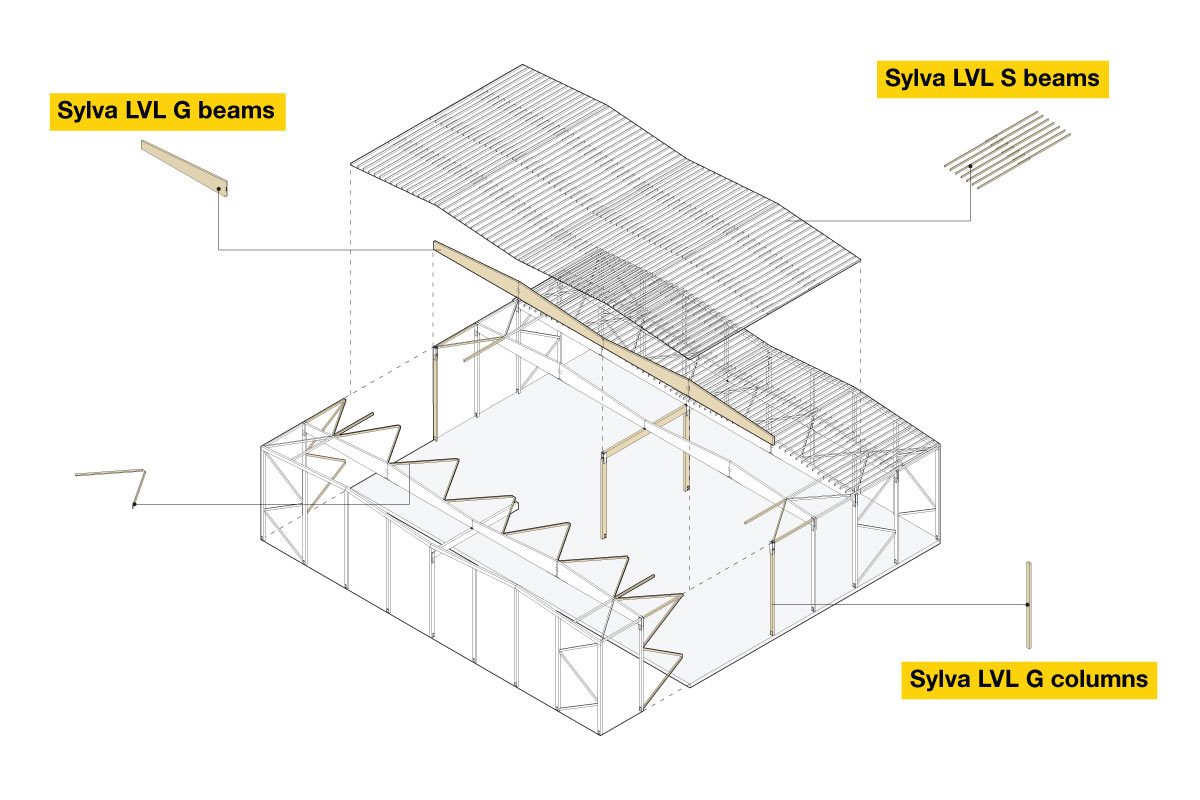

All our LVL products are certified and sourced from sustainably managed forests. When LVL by Stora Enso is customized and delivered just-in-time, it is part of our Sylva™ kit:

*Sylva™ by Stora Enso is currently only available in Europe and Australia.

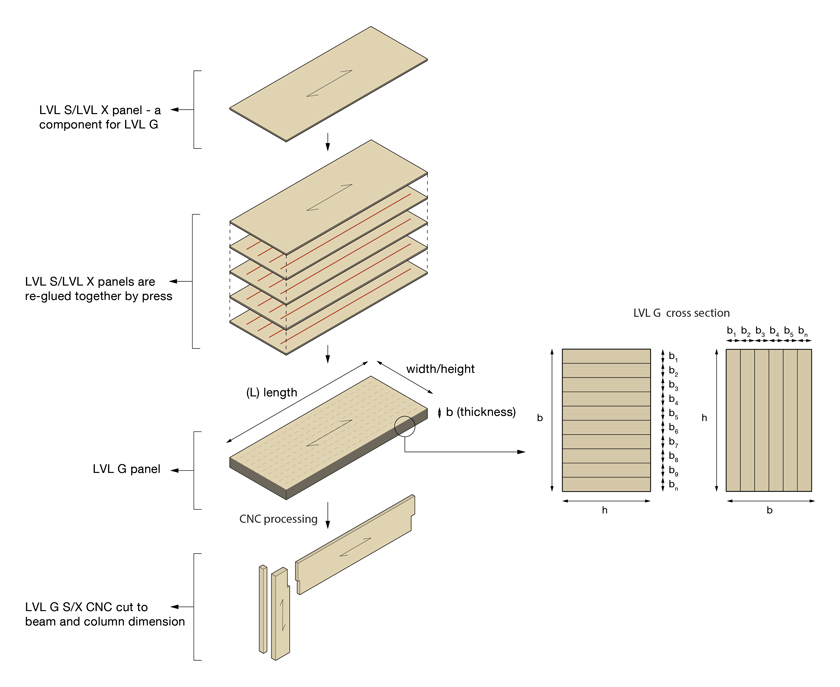

LVL by Stora Enso is made from 3 mm thick veneers bonded together with high-strength adhesive. The logs used to manufacture LVL are peeled and dried so any natural defects in the wood are spread throughout the veneer. Together with the lamination effect, this results in straight and uniform material with high strength and stiffness.

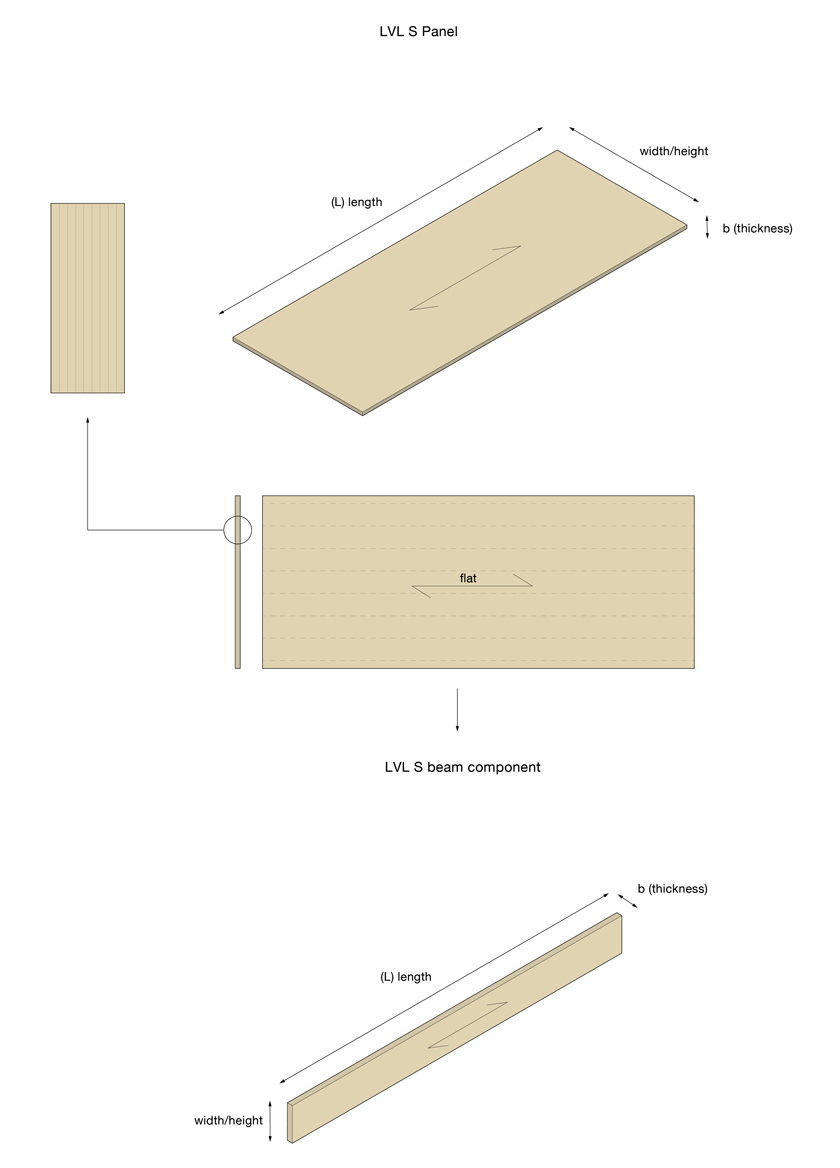

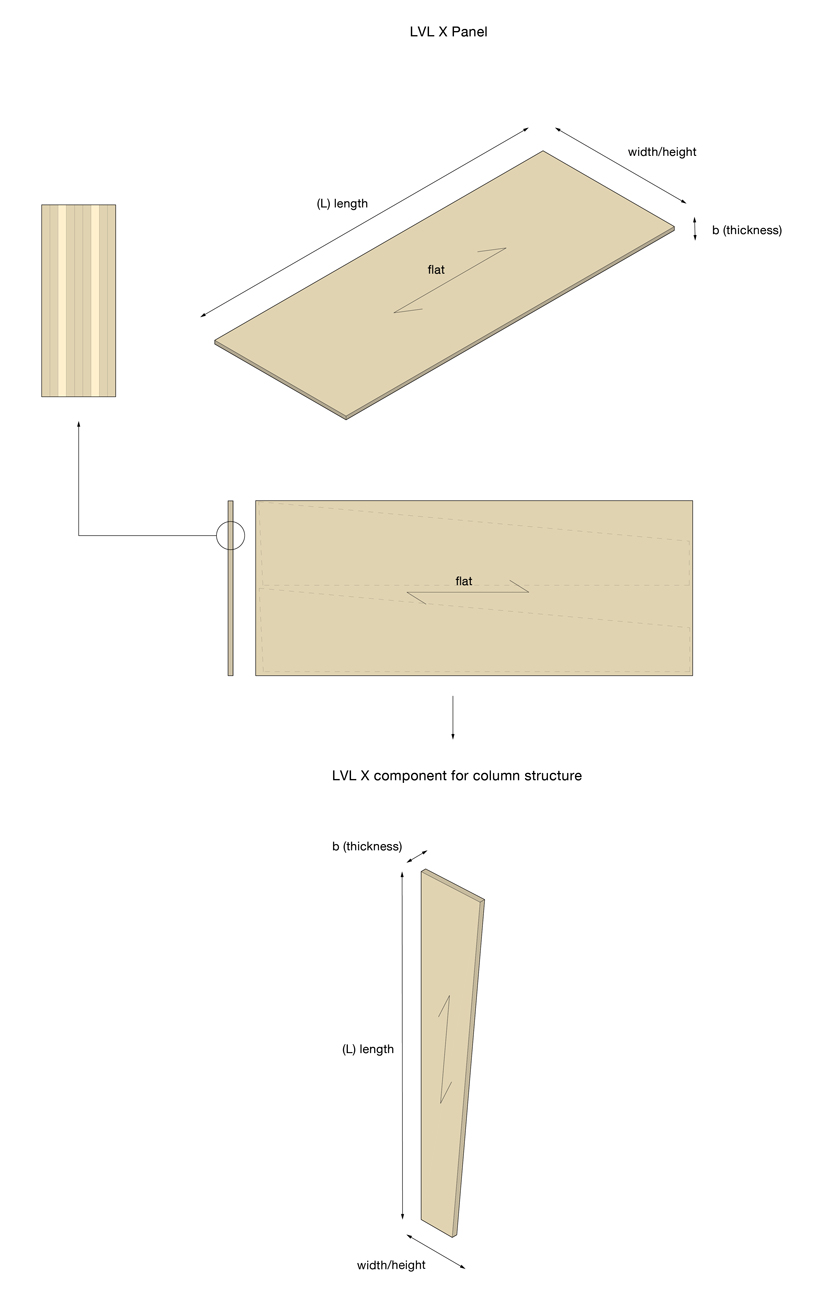

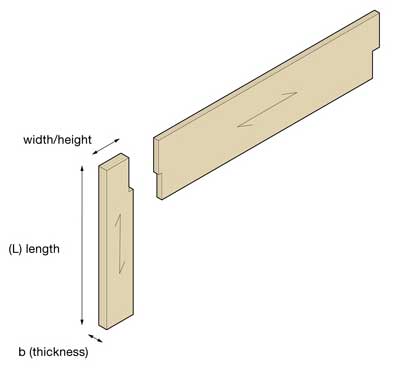

LVL beams and columns are available in max size of panels 24,000 mm x 2,400 mm x 75 mm that are format cut and CNC-processed to the desired dimensions. For thickness greater than 75 mm, Stora Enso offers LVL G beams and columns that are made by regluing the LVL panels together flatwise.

Light but strong —twice as strong as steel proportionate to weight and five-times lighter than concrete

Homogenous and dimensionally stable, with no warps, splinters, or splits

Sylva LVL beams and columns are prefabricated and delivered just in time (JIT) to reduce construction waste and increase build efficiency

For primary and secondary beam and column applications, LVL S and LVL GS are recommended. Where openings are required in beams or where more lateral stiffness is required to prevent buckling, LVL X and LVL GX are recommended.

Discover the possibilities of mass timber with our 3D tool

Standard panel variants

Length: max 24,000 mm

Thickness: max 75 mm

Width: max 2,400 mm

| LVL S product range for beam applications | |||||||||||

| thickness [mm] | Width/Height up to 2,400 mm | standard length [mm] | |||||||||

| 200 | 220 | 260 | 300 | 360 | 400 | 600 | |||||

42 |

|

13,500 |

|||||||||

45 |

|||||||||||

51 |

|||||||||||

63 |

|||||||||||

75 |

|||||||||||

| LVL X product range | |||||||||

| thickness [mm] | Width/Height up to 2,400 mm | standard length [mm] | |||||||

| 400 | 600 | 1,200 | 2,400 | ||||||

30 |

|

13,500 |

|||||||

39 |

|||||||||

45 |

|||||||||

51 |

|||||||||

63 |

|||||||||

75 |

|||||||||

| LVL G S/X product range for beam and column applications | |||||||||

| thickness [mm] | Width/Height up to 2,400 mm | standard length [mm] | |||||||

| 290 | 330 | 390 | 450 | 590 | 790 | 1,180 | |||

84 |

|

up to 19,900 |

|||||||

96 |

|||||||||

108 |

|||||||||

126 |

|||||||||

144 |

|||||||||

168 |

|||||||||

192 |

|||||||||

240 |

|||||||||

288 |

|||||||||

336 |

|||||||||

| Width/height are recommended dimensions to optimise the use of the raw material. LVL G product surface is calibration sanded. * Larger dimensions can be made available upon request. Please contact your local sales representative for more information. |

|||||||||

Browse over 500 wooden buildings and get inspired

| Service class | Service class 1 and 2 according to EN 19951–1 |

| Product certification | LVL is CE marked according to EN 14374 LVL G has ETA-approval ETA 20/0291 |

| Strength class | LVL according to EN14374 and LVL G according to ETA 20/0291 |

| Moisture content | 10 % +/- 2% |

| Wood species | Spruce |

| Mean density | 510 kg/m³ (characteristic density 480 kg/m³) |

| Reaction to fire class | Euroclass D–s2, d0 |

| Resistance to fire, charring rate | According to Eurocode 5 βn =0.70 mm/min (notional charring according to EN 1995–1–2) |

| Thermal conductivity | 0.13 W/(mK) |

| Water vapour resistance | Wet cup 70 Dry cup 200 |

LVL S/X and LVL G grades are manufactured in a modern, factory controlled environment and cut to size with highly accurate CNC processing. Exceptional size accuracy minimises the need for remedial work when the prefabricated elements are delivered on site, which speeds up the building process and reduces construction costs.

| LVL S/X tolerances | ||||

| Length | +/- 2.0 mm | |||

| Thickness | Unsanded | Sanded* | Calibrated** | |

| 27 mm | +/- 1.0 mm | +/- 1.0 mm | +/- 0.5 mm | |

| 27-57 mm | +/- 2.0 mm | +/- 2.0 mm | +/- 0.5 mm | |

| 57-75 mm | +/- 3.0 mm | +/- 3.0 mm | +/- 0.5 mm | |

| Width | +/- 2.0 mm | |||

* LVL panels can be sanded on one or two sides. Sanding reduces panel thickness by approx. 1 mm per sanded side.

** Calibration increases the panel's thickness tolerances. An LVL panel is calibrated on two sides, which reduces the thickness by 3 mm in total (1.5 mm per side).

Tolerances for standard cutting in LVL production: Element length +/- 5 mm , Width for < 400 mm element +/- 2mm and for > 400 mm +/- 0,5 %”

| LVL G S/X tolerances | |

| Length | +/- 2 mm |

| Thickness | +/- 3 mm |

| Width | +/- 2 mm |

Wood shrinks or swells as its moisture content changes, but in LVL this is minimal because of the lamination process.

|

Direction |

% of shrinkage or swelling per % moisture change |

|

Direction of length (L) |

LVL S/LVL G S +/- 0.006, LVL X/ LVL G X +/- 0.009 |

|

Direction of width (w/h) |

LVL S/LVL G S +/- 0.31, LVL X/LVL G X +/- 0.033 |

|

Direction of thickness (b) |

LVL S/LVL G S +/- 0.30, LVL X/LVL G X +/- 0.44 |

Calculatis: a state-of-the-art timber design tool

The wood used in Sylva LVL beams and columns originates from sustainably managed European forests. Like all Stora Enso wood products, it is third-party certified by traceability and chain of custody systems, FSC®*, PEFC, or both.

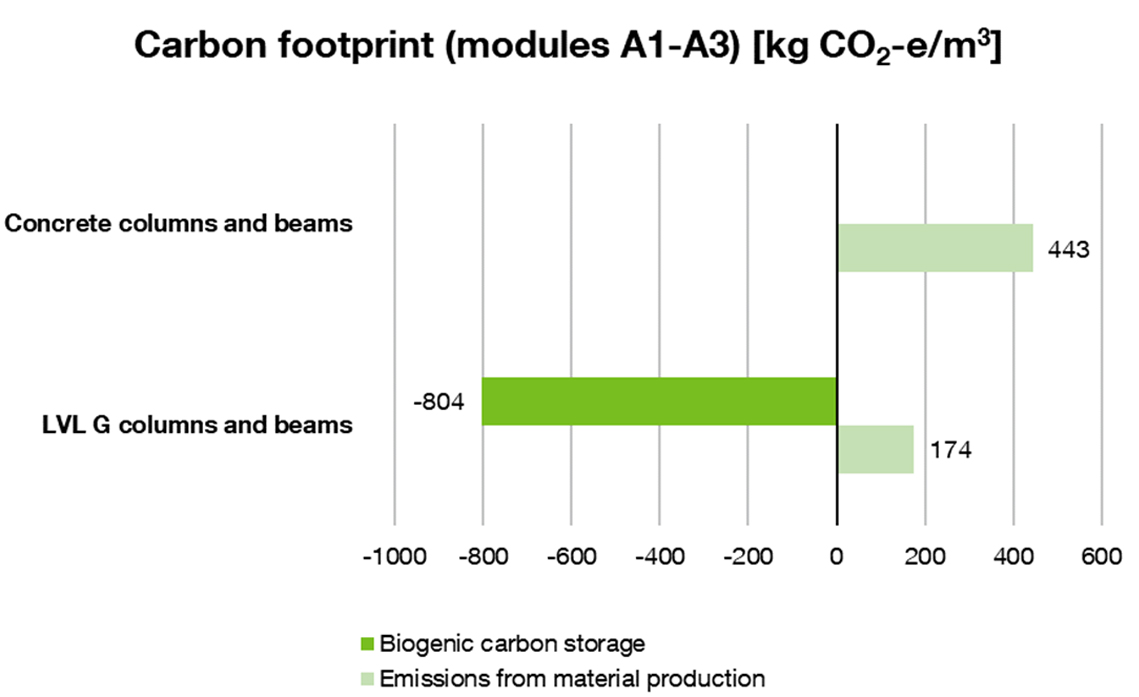

The energy used to manufacture LVL is very low. And compared with other construction materials the carbon stored in LVL is high for example, 1 m³ of LVL stores 804 kg CO₂.

FSC® trademark licence C125195

Sylva LVL beams and columns deliver superior sustainability performance over mineral-based alternative materials. Following is a comparison of material manufacturing emissions of a Sylva LVL beam and an equivalent steel-reinforced concrete.