Cross-laminated timber (CLT) is a mass timber product that can replace concrete and steel in modern construction. As buildings become more sustainable and timber structures grow larger, CLT has become a popular solution for floors, roofs, walls, and stairs due to its strength, appearance, and versatility.

Photo: Belén Imaz/ÁBATON Arquitectura/Madergia

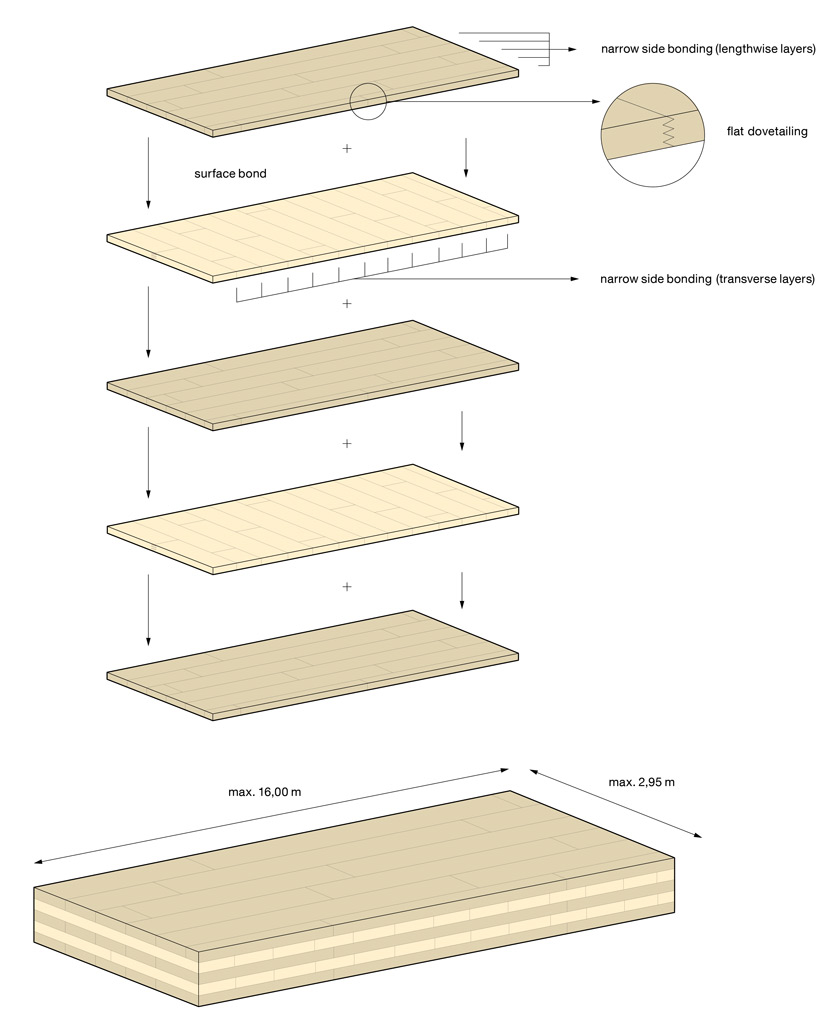

CLT is made from several layers of solid wood panels bonded with a structural adhesive at alternating right angles. It is ideal for large floor, roof, and wall elements, where mass timber can significantly reduce CO2 emissions compared to concrete and steel.

Cross-laminated timber is well known for its strong load-bearing qualities. It is a sustainable alternative to concrete and steel thanks to its acoustic, fire, seismic and thermal performance. CLT by Stora Enso is available from PEFC or FSC-certified softwood.

CLT by Stora Enso that is customised and delivered just-in-time (JIT) is part of our Sylva™* kit, where it can be used in a variety of applications:

*Sylva™ by Stora Enso is currently only available in Europe and Australia.

CLT by Stora Enso is made of at least three single-layer panels that are bonded together with high-strength adhesive at a right angle. Each layer consists of a set of strength-graded boards that are finger-jointed and bonded together edge to edge. When these strong and stiff layers are bonded and pressed together, they form CLT panels that can be up to 16 m long.

Cut emissions by up to 70%, compared with concrete and steel

Rapid assembly and construction on-site saves time and can lower total costs

Strong, stiff, stable and can handle transfer load in two directions

Achieve good thermal and sound insulation, and create a comfortable and healthy indoor climate

Our Sylva CLT applications can provide adequate fire resistance to meet fire regulations

A range of visual grades allows you to experience the real natural look and feel of wood

Strong, robust, visually appealing, and CE-marked building components ETA-14/0349

Bespoke and prefabricated building products delivered just in time (JIT) to a construction site

Save up to 10% more living space

Can take on very high loads compared to timber frame walls, making them ideal for mid-rise buildings

Sylva CLT Floors and Roofs are the slimmest flooring option amongst wood alternatives for short to medium spans

Prefabricated as one element for rapid installation and instant access to the working level

Replaces the need for temporary construction stairs

Cut to precision with no forming and curing time required

Perfect fit in wooden construction—delivered at the same time as other elements and installed by the same tradespeople

Discover the possibilities of mass timber with our 3D tool

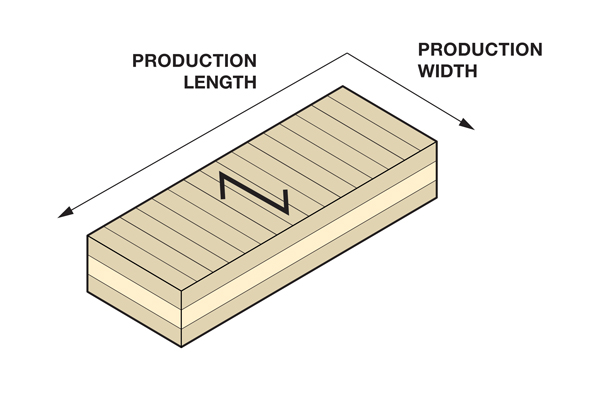

Panel where the top layers are at right angles to the production length of the panel. Most often used for walls.

Standard variants

C-panels are available in 3 or 5 layers

Max length: 16 m

Max thickness: 160 mm

Max width: 3.45 m*

Charged widths

2.25, 2.45, 2.75, 2.95, 3.25*, 3.45* m

* Please contact your local sales representative for more information regarding the larger dimensions.

CLT type C The grain direction of the cover layers is always parallel to the production widths. |

||||||||||||

| Thickness [mm] | Type [-] | Layers [-] | Variant [mm] | |||||||||

| C* | L | C* | L | C* | L | C* | ||||||

| 60 | C3s | 3 | 20 | 20 | 20 | |||||||

| 70 | C3s | 3 | 20 | 30 | 20 | |||||||

| 80 | C3s | 3 | 20 | 40 | 20 | |||||||

| 90 | C3s | 3 | 30 | 30 | 30 | |||||||

| 100 | C3s | 3 | 30 | 40 | 30 | |||||||

| 110 | C3s | 3 | 40 | 30 | 40 | |||||||

| 120 | C3s | 3 | 40 | 40 | 40 | |||||||

| 100 | C5s | 5 | 20 | 20 | 20 | 20 | 20 | |||||

| 120 | C5s | 5 | 30 | 20 | 20 | 20 | 30 | |||||

| 140 | C5s | 5 | 40 | 20 | 20 | 20 | 40 | |||||

| 150 | C5s | 5 | 40 | 20 | 30 | 20 | 40 | |||||

| 160 | C5s | 5 | 40 | 20 | 40 | 20 | 40 | |||||

* Sanding direction is perpendicular to the grain |

||||||||||||

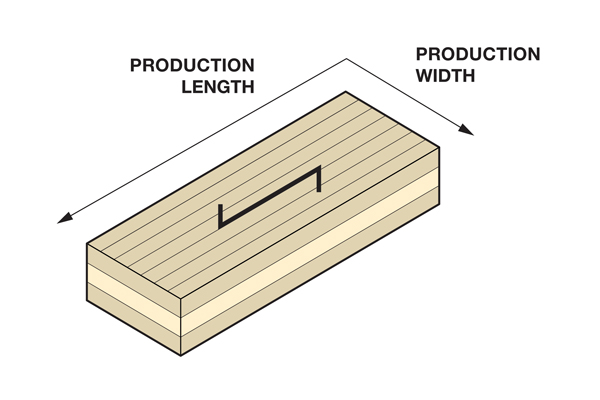

The top layers are parallel to the production length of the panel. Most often used for floors and roofs.

Standard variants

CLT type L is available in 3, 5, 7 or 8 layers

Max length: 16 m

Max thickness: 320 mm

Max width: 3.45 m*

Charged widths

2.25, 2.45, 2.75, 2.95, 3.25*, 3.45* m

* Please contact your local sales representative for more information regarding the larger dimensions.

CLT type L The grain direction of the cover layers is always perpendicular to the production widths. |

|||||||||

| Thickness [mm] | Type [-] | Layers [-] | Variant [mm] | ||||||

| L | C | L | C | L | C | L | |||

| 60 | L3s | 3 | 20 | 20 | 20 | ||||

| 70 | L3s | 3 | 20 | 30 | 20 | ||||

| 80 | L3s | 3 | 20 | 40 | 20 | ||||

| 90 | L3s | 3 | 30 | 30 | 30 | ||||

| 100 | L3s | 3 | 30 | 40 | 30 | ||||

| 110 | L3s | 3 | 40 | 30 | 40 | ||||

| 120 | L3s | 3 | 40 | 40 | 40 | ||||

| 100 | L5s | 5 | 20 | 20 | 20 | 20 | 20 | ||

| 120 | L5s | 5 | 30 | 20 | 20 | 20 | 30 | ||

| 140 | L5s | 5 | 40 | 20 | 20 | 20 | 40 | ||

| 150 | L5s | 5 | 40 | 20 | 30 | 20 | 40 | ||

| 160 | L5s | 5 | 40 | 20 | 40 | 20 | 40 | ||

| 180 | L5s | 5 | 40 | 30 | 40 | 30 | 40 | ||

| 200 | 5Ls | 5 | 40 | 40 | 40 | 40 | 40 | ||

| 160 | L5s-2* | 5 | 60 | 40 | 60 | ||||

| 180 | L7s | 7 | 30 | 20 | 30 | 20 | 30 | 20 | 30 |

| 200 | L7s | 7 | 20 | 40 | 20 | 40 | 20 | 40 | 20 |

| 240 | L7s | 7 | 30 | 40 | 30 | 40 | 30 | 40 | 30 |

| 220 | L7s-2* | 7 | 60 | 30 | 40 | 30 | 60 | ||

| 240 | L7s-2* | 7 | 80 | 20 | 40 | 20 | 80 | ||

| 260 | L7s-2* | 7 | 80 | 30 | 40 | 30 | 80 | ||

| 280 | L7s-2* | 7 | 80 | 40 | 40 | 40 | 80 | ||

| 300 | L8s-2** | 8 | 80 | 30 | 80 | 30 | 80 | ||

| 320 | L8s-2** | 8 | 80 | 40 | 80 | 40 | 80 | ||

* Cover layers consisting of two lengthwise layers ** Cover layers and middle layers consisting of two lengthwise layer |

|||||||||

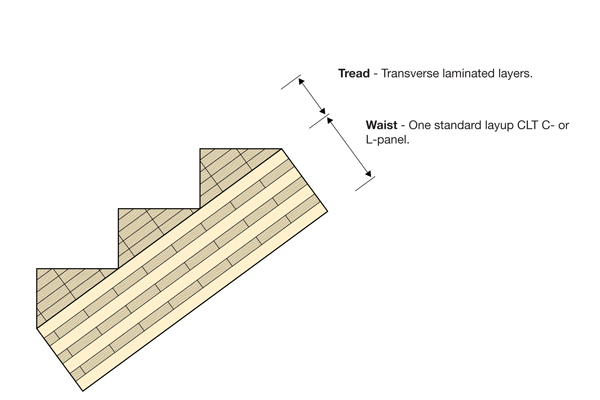

Our CLT stairs comes prefabricated and ready for installation. The waist of the stairs is made of standard C or L-type panels and the stair treads are formed from non-loadbearing transverse layers which makes the stairs more robust on the building site. With very little exposed end-grain, CLT stairs have enhanced resistance to damage and moisture.

CLT stairs can be processed into almost any shape, please contact your local sales representative for more information.

CLT by Stora Enso is available in three different surface qualities. Below are examples of the respective quality, for a detailed description of the respective surface quality please refer to our surface quality chart.

Please note that visual quality is only available on the soffits (underside) when applied to Sylva CLT Stairs.

Non-visual quality (NVI)

Suitable for when the CLT is not visible or when it will be covered with gypsum, plasterboard, or any other material.

Industrial Visual Quality (IVI)

A surface quality suitable for leaving exposed, but not with the most demanding visual requirements, for example, up high on a ceiling. This grade is commonly used in Industrial buildings or sports halls.

Visual quality (VI)

Browse over 500 wooden buildings and get inspired

| Service class | Service class 1 and 2 according to EN 1995-1-1 |

| Product certification | CE-marked with ETA 14/0349 |

| Strength class | C24 maximum 10% C16 permitted according to ETA (C24 maximum 10% C16 permitted lamellas) |

| Moisture content | 6% to 15% according to EN 13183-2 |

| Wood species | Spruce (pine, fir, stone pine/larch and other wood types on request) |

| Weight/density | 490 kg/m3. Please note a different density may be declared depending on the need (structural design, transportation, erection etc.) |

| Reaction to fire class | Sylva CLT Walls: Euroclass D-s2, d0 Sylva CLT Floors and Roofs: Euroclass D-s2, d0 |

| Resistance to fire, charring rate | Sylva CLT Walls: Cover layer 0.63 mm/min | More than cover layer* 0.86 mm/min Sylva CLT Floors and Roofs: Cover layer 0.65 mm/min | More than cover layer* 1.3 mm/min According to ETA 14/0349 * More than cover layer 1.3 mm/min until 25 mm of charring. Afterwards, the charring rate of 0.65 mm/min on floors only applies up to the next glue line. |

| Airtightness | CLT is airtight according to EN 12 114 |

| Thermal conductivity | 0.12 W/(mK) according to ETA 14/0349 |

| Vapour permeability | 50 (dry) to 20 (wet) according to EN ISO 10456 |

The surface and finger joints are bonded with a polyurethane adhesive (PUR) that is approved for load-bearing and non-load-bearing components indoors and outdoors according to the EN 15425 classification. The narrow side is bonded with an EPI or PUR adhesive.

The formaldehyde-free adhesives that we use do not pose a health hazard and the quantities are reduced as far as possible in compliance with the necessary requirements resulting in a fraction of glue at 1%. This all results in very low volatile organic compounds (VOC) levels where CLT meets the most demanding indoor climate requirements.

CLT by Stora Enso is manufactured in modern, factory-controlled environments and cut to size with highly accurate CNC processing. Exceptional size accuracy minimises the need for remedial work when the prefabricated elements are delivered on site, which speeds up the building process and reduces construction costs.

CLT by Stora Enso tolerances are according to standard DIN 18203-2.

Because CLT is cross-laminated, the effects of swelling and shrinking from changes in moisture content are minimized. Standardized values are:

| Direction | % of shrinkage or swelling per % moisture change |

| Grain direction | +/- 0.02-0.04 |

| Cross grain direction | +/- 0.24 |

Calculatis: a state-of-the-art timber design tool

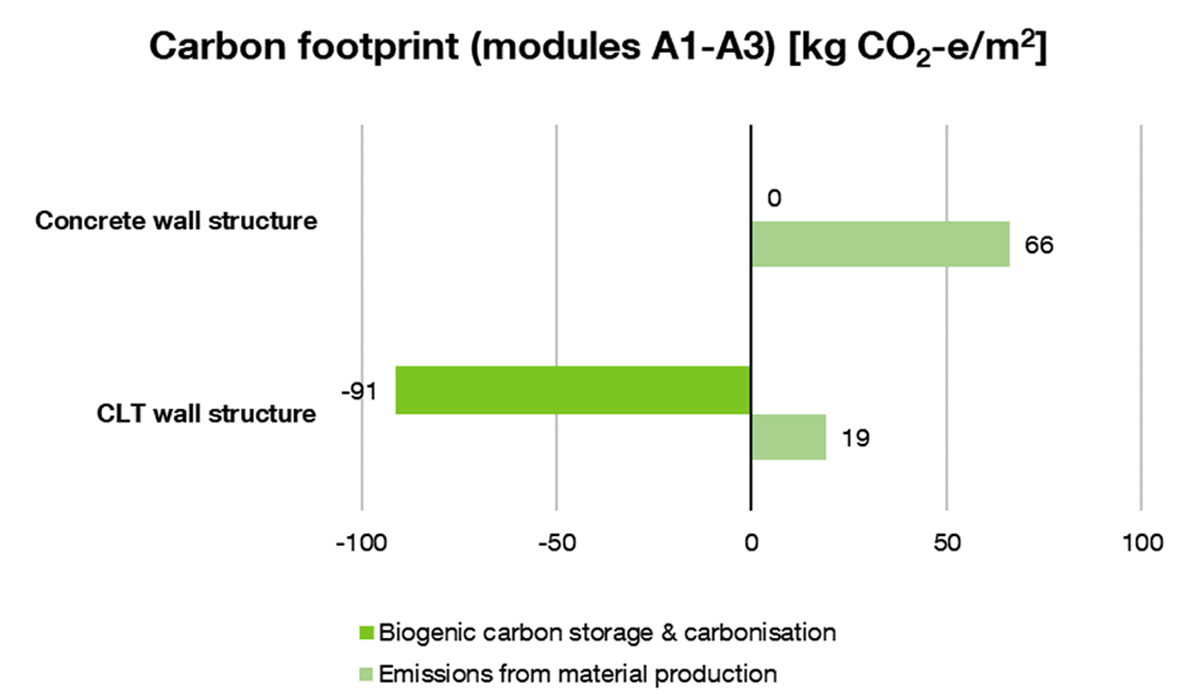

Below is a CO2 eq. emissions comparison* between a typical external wall structure made from CLT and one made from concrete. The result speaks for itself. Manufacturing the CLT wall structure emits significantly less CO2 eq., but it also stores carbon, locking it in the building for decades.

The compared wall structures are as follows:

External concrete wall assembly, U-value 0.18 W/m²K

External CLT wall assembly, U-value <0.17 W/m²K

Assumed building: European 3–8 storey residential building

The dataset used for this comparison:

* Comparison of the CO2 eq. emissions per m² of the product carbon footprint (modules A1-A3 greenhouse gas emissions associated with materials and construction processes up to practical completion). Does not include the CO2 eq. sequestered in the installed products at practical completion.

Stora Enso is a global leader for low carbon impact in our manufacturing processes. CLT by Stora Enso is produced with only renewable electricity in our production units in Austria and CO₂ fossil-free energy in our Swedish production units.